1. High Accuracy and Precision Cuts - Laser cutting uses an extremely small, powerful laser which delivers a focused beam of light to the material it’s cutting with extreme precision. When extremely high accuracy and precision are required, laser cutters are almost always the best choice. This is one of the reasons that laser cutting is often used in the aerospace industry, where tolerances are extremely tight.

2. Low Lead Times with Lower Costs - One of the best benefits of a laser cutter is that it’s economical to use laser cutting even for limited-run projects. This is because a laser cutter does not use any kind of tooling that must be custom-built or modified for your project. It also does not have physical cutting surfaces which wear out. Laser tools also have fewer mechanical moving parts, which reduces maintenance and operations costs and helps keep the cost of using a laser cutting company low.

3. Handle Job Complexity - The high-powered laser can be used to work on a very narrow section of material and causes very little warping or distortion to the area being cut. With the proper schematic, a laser cutter can be used to quickly and easily create even the most highly-complex geometries and cuts with unparalleled precision and excellent tolerance levels.

4. Higher Sheet Utilization with Less Waste - Another benefit of the precision and accuracy of laser cutting is that it can utilize a very high percentage of your sheet material. Again, this leads to lower overall costs for your project and faster completion times. Less time is needed to swap in new sheets of material, and less of your raw material is wasted by the machining and cutting process.

5. Causes No Damage Or Warping - A common misconception about laser cutting is that the high heat causes a lot of distortion and warping. But this is not true. Lasers are actually ideal for cutting extremely thin materials. The laser cuts through the material so quickly that it will not become excessively hot and warp.

6. Low Power Consumption - While the laser used to cut materials uses quite a bit of energy, laser cutters do not have any other moving parts – unlike presses and some other cutting tools, which require enormous amounts of energy to deliver cutting force using a physical die. It helps decrease overall running costs, and also reduces the overall impact of laser cutting machines on the environment.

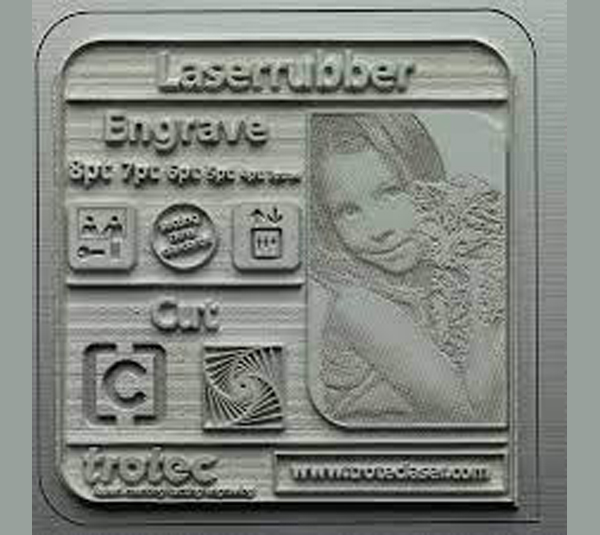

7. Extreme Cutting Versatility — Can be Used on Almost any Material: - Lasers can also be used for drilling, marking, and engraving, just to name a few functions – without needing to replace or switch any tooling. Not only that, but laser cutters can be used on almost any material. A laser cutter can be used to cut just about anything. While lasers are not usually suitable for extremely thick metals – where a water jet or plasma cutter may be recommended – the versatility of laser cutting makes it a critical part of modern machining.